Metal processing/stamping

High-precision stamping tools and complex progressive tools are used here. The design is carried out in-house by experienced designers in close co-operation with the production department.

Technology:

Production of stamped parts

With our presses, which achieve a pressure force of up to 500 kN, we produce various stamped parts for our own requirements. These include power contacts, stamped grids, shielding plates and busbars. We process materials in strip thicknesses of 0.15 to 2.00 mm and strip widths of up to 150 mm. We use high-quality contact materials such as high-performance copper alloys and stainless steel. Thanks to our in-house production, we can guarantee short production times and react flexibly to any challenges that may arise.

Technology:

Pin production

We manufacture pin and signalling contacts with a square or round cross-section. We produce over 100 million square pins with an edge length of 0.63 mm and pin lengths between 12 mm and 60 mm for our own requirements every year. The grid dimensions 2.50 mm, 2.54 mm and 4.00 mm are currently standardised. However, thanks to our flexible production machines, we can also realise individual customer requirements.

Technology:

Welding processes

Here we join two metal bodies using contact welding processes, such as resistance welding. This process makes it possible to combine different geometries and materials.

Technology:

Surface technology

Together with long-standing partners in the field of surface finishing, we take care of the appropriate coating of the stamped parts, from reflow-resistant tin coatings to gold and silver coatings and indium surfaces for press-fit contacts.

Plastics processing/ injection moulding

Injection moulding of highly sophisticated parts has been one of our core manufacturing competencies for over 30 years. Highest precision in all product sizes characterises our performance profile. We manufacture technically sophisticated plastic parts on state-of-the-art injection moulding machines with clamping forces of up to 800 kN. Products with inserts can also be manufactured manually or in fully automated production processes, depending on the quantity and customer requirements. SPC monitoring of the part geometry and preventive maintenance of the injection moulding tools ensure the consistently high quality of the plastic parts.

Technology:

Plastic injection moulding and multi-component injection moulding

We have a plastic parts production facility with more than 35 injection moulding machines of various sizes for both complex 1-component parts and multi-component injection moulding. The combination of several types of thermoplastic in one component enables us to combine different material properties to meet our customers' requirements. We optimise process costs to a minimum with manual, semi-automatic or fully automatic processes tailored to the quantity.

Technology:

Metal overmoulding/

Hybrid technology

At H&B, we manufacture plastic and metal composite parts using hybrid technology. We overmould our stamped parts with plastic in partially and fully automated production lines. By integrating other technologies, such as the overmoulding of metal screw-on bushes, the application of DAE (pressure equalisation elements) and many others, we manufacture the most complex assemblies and thus offer comprehensive solutions from a single source.

Based on economic and quality aspects, we decide whether to use insert technology (insertion of metal inserts, e.g. lead frames, bushes etc. for overmoulding), reel-to-reel processes, workpiece carrier circulation systems or reel-to-piece processes (combination of injection/punching process).

Technology:

Hard-soft connections

We have been manufacturing parts using the 2-component process for over 20 years. In this process, a hard component (thermoplastic) is moulded with a soft component (elastomer) in an injection moulding process to form a composite part. The bond between the different materials creates an excellent adhesive effect - a very efficient and economical process. The 2-component technology is ideal for parts with large quantities. For smaller quantities, two separate processes are used and - if necessary - with appropriate pre-treatment such as plasma activation.

Technology:

Hotmelt processing

We achieve composite parts through the use of hot-melt adhesives. They fulfil the sealing requirements of our customers. These include media-tight connectors, waterproof electronic components and IP69-K tested sensors.

Technology:

Elastomer and LSR processing

Using this technology, we manufacture moulded parts, damping elements, membranes and moulded seals from all common elastomers with a focus on liquid silicone (LSR). One speciality is the direct injection of LSR onto a thermoplastic using the 2K process. Another area of application can be the encapsulation of electronic components and electrical connections.

Assembly industry

The possibilities of our assembly department range from manual assembly for small series to fully automated assembly for large series. We develop and realise optimal assembly solutions. All customer requirements in terms of annual quantities, production batch size, quality and documentation are taken into account in the decision-making process together with the customer. In the field of industrial technology, we realise lean and technologically diverse production processes for smaller quantities and a wide range of variants.

Technology:

Assembly techniques

Screwing, joining, riveting, toxing, press-fitting, hot caulking or the assembly of various components - we use these technologies with a well thought-out process flow and also offer other processes such as printing, labelling and packaging in customer-specific packaging materials. Series-accompanying or 100 per cent inspections, such as electrical testing, leak tests and/or camera inspections, are obligatory.

Technology:

Bonding, potting, sealing

The potting technology enables precise dispensing of high-quality potting compounds directly on the component. The potting functions for the product are very diverse, with the focus often being on tightness against various media (IP69K, oil tightness, etc.).

Technology:

Welding processes

We use laser and ultrasonic welding processes to join a wide variety of plastic components together or process membranes for pressure equalisation.

Technology:

Cable assembly

We assemble cable harnesses for applications in medical technology, the automation sector and industrial electronics. We have many years of experience in crimping and soldering connections, as well as in cutting and clamping technology. H&B has also been realising the overmoulding of cables for many years.

Technology:

Printed circuit board processing

Together with long-standing partners, we assemble a wide variety of circuit boards on behalf of customers, including for applications in the automotive sector. We also use our own developments for PCB connection technology. The experience gained in this area can be utilised directly for new developments, thus ensuring optimum customer benefit.

Automotive assembly

We develop and realise optimal assembly solutions. The possibilities of our assembly department range from manual assembly for small series to fully automated assembly for large series. All customer requirements in terms of annual quantities, production batch size, quality and documentation are taken into account in the decision-making process together with the client. We realise both very small series and batch sizes of over 40,000 units per day for automotive applications.

Technology:

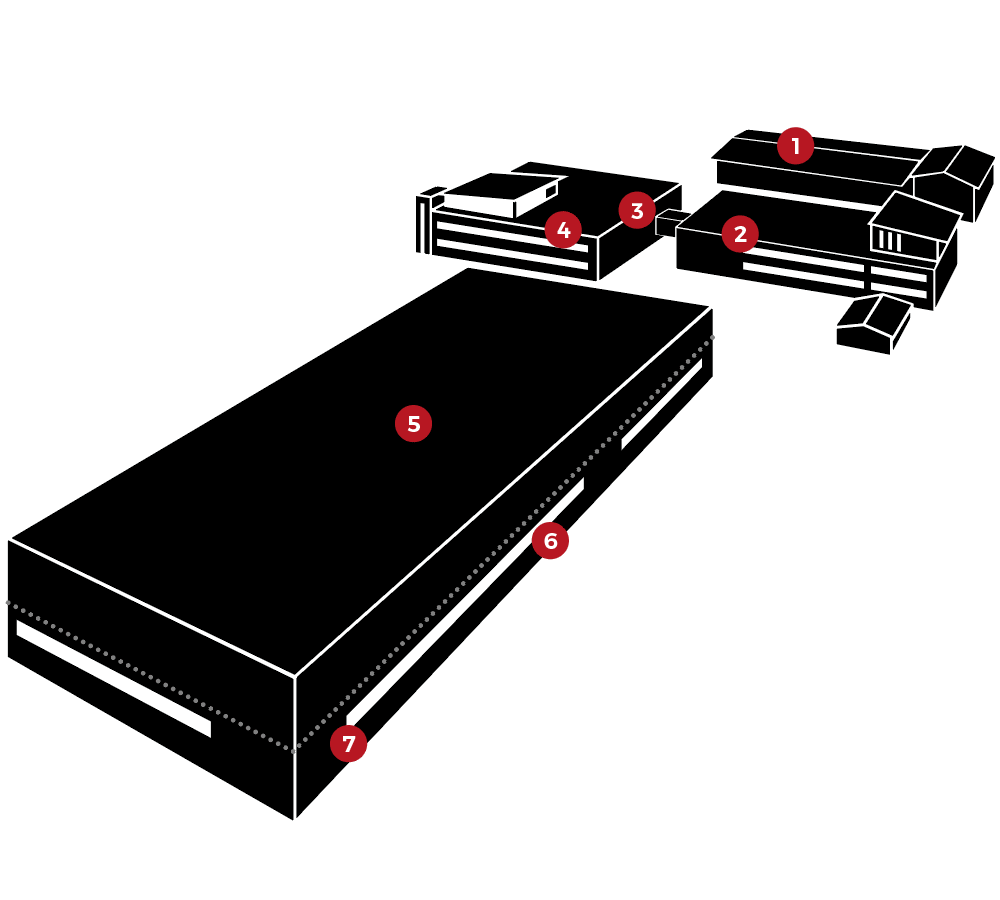

Stitching or press-fitting of metal contacts

With the help of mainly fully automatic insertion machines, we are able to assemble square pins, lead frames and also flat contacts of various cross-sections (e.g. 1.5, 2.8, 4.8, 9.5 contacts and many more) in a wide variety of grids. Straight or bent at 90°, single-row or up to 4-row - the focus is on customised products and an optimised production process.

As part of our OPEX (Operational Excellence) strategy, we pursue a continuous improvement process.

Technology:

Prototype production

For prototypes, pre-series and small series, we offer production in classic manual assembly if required. We can use various alternative manufacturing processes, such as water jet or laser cutting of contacts and the production of plastic parts using STL, 3D printing or special prototype injection moulding tools. We never lose sight of scalable production so that the prototypes can also be produced economically in series quantities at a later date and optimum stage concepts for quantity adjustments (start-up and discontinued production) can be realised.

Medical production

We have been manufacturing injection systems and products for medical technology exclusively and 100% in Germany since 1997. This separate production area is certified accordingly and is regularly audited. The focus here is on various assembly processes, which are realised by specially trained personnel with many years of experience.

Toolmaking

The company's in-house toolmaking department enables short lead times even for technically demanding and very extensive projects. All basic technologies required for the manufacture of injection and punching tools, assembly devices and special machines are available in-house.

High-precision stamping tools, complex multi-cavity injection moulding tools or devices and components for the automation lines - they are all designed in-house by experienced designers in close cooperation with the production department and implemented using our modern machinery. We utilise several die-sinking EDM machines, wire-cutting machines, profile grinding machines, surface grinding machines, HSC milling machines and various CNC milling machines.

We regularly update our technologies (e.g. 5-axis milling and graphite milling) and also use the latest processes such as metal 3D printing. The high level of vertical integration enables us to realise projects optimally and meet the confirmed completion dates for tools.

Metal 3D printing

An injection moulding tool with near-contour temperature control from the 3D printer without sacrificing the tried-and-tested 1.2343 (H11) tool steel? Until now, there were hardly any service providers on the market offering printed mould inserts made from 1.2343 (H11). Driven by the high demands on the quality and cost-effectiveness of our plastic components and injection moulding tools, we decided to enter the field of metal 3D printing. With printed mould inserts made of 1.2343 (H11), we achieve the best performance through the combination of near-contour tempering and hot-work tool steel. Advantages that not only benefit our own plastic components. As a service provider, we also offer you as a customer 3D printed mould inserts so that your components are also a decisive step ahead in terms of quality and cost-effectiveness.

Automation technology

Our in-house special-purpose machinery enables us to provide customised, partially or fully automated assembly for large series. Creativity is part of our specialists' daily work. Highly automated production lines with over five industrial robots and four punching units or compact, sophisticated semi-automatic machines with collaborating robots - the aim is always to achieve cost-effective production over the entire product life cycle. Special expertise lies in the development of step-by-step concepts and scalable production processes, so that efficient production can be achieved even with small units, even for "high mix - low volume" projects.